Test bench solutions

for electrical and electromechanical components

Turnkey test stands made by the experts

We develop modern and versatile test benches for research, development and production. We use a first-class measurement hardware and software platform. With our experienced test bench team, we accompany you in all phases of your project: from planning to design and assembly to realization. We are also happy to support you in modernizing existing systems and protect your investment in the future.

Our test benches are used for testing the following objects:

- Electric motors (DC, EC, AC)

- Gearboxes and motor-gearbox combinations, e.g. window lifter or windshield wiper drives

- Electric motors with integrated electronics, such as e-bike drives, scooter drives or electric refrigerant compressors

- Electronics

- Batteries

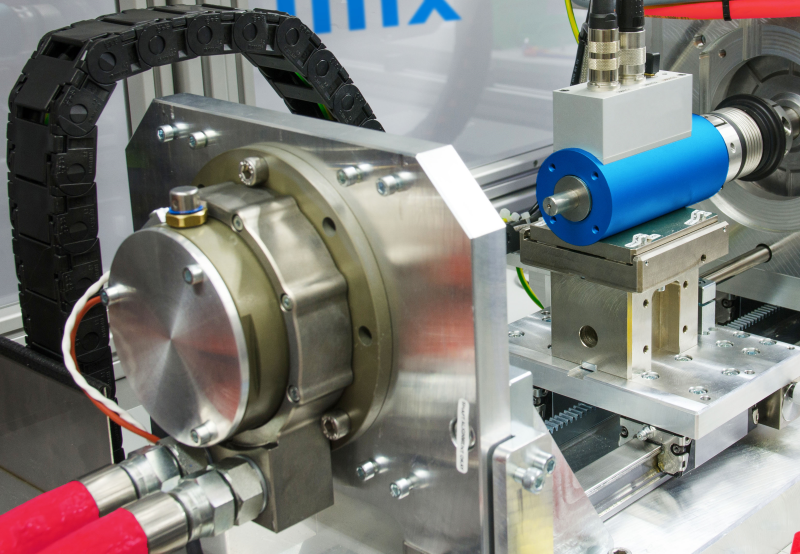

Development test benches

The development test benches from imx are known for their high flexibility in testing electric motors and components. A wide variety of motor types can be tested and a variety of tests can be realized. The mechanical setup consists of a test bed with load machine and torque measuring shaft. The load machine and measuring shaft are mounted on a linear guide and precisely aligned axially using a laser. As a unit, they can be moved linearly. Particularly time-saving: When changing the torque sensor, no realignment of the load train is necessary.

The setup with an active drive machine (as PMSM synchronous motor or asynchronous machine, depending on the test task) as load unit, extends the range of tests:

- Measurement of the regenerative force (EMF) or also called Back EMF

- Cogging torque measurement at low speed with 0.5 … 10 rpm

- Dragging the DUT and controlling in 0 Nm torque range

- Determination of torque ripple at defined speeds

- Dynamic load of the test specimen

- Effect of interferences on the DUT

- Components and electronics tests according to LV-123, LV-124, LV-147 and LV-148

The setup with a passive brake (induction brake, magnetic particle brake, or similar) is also possible and useful for special applications, such as acoustic measurements or very high speeds.

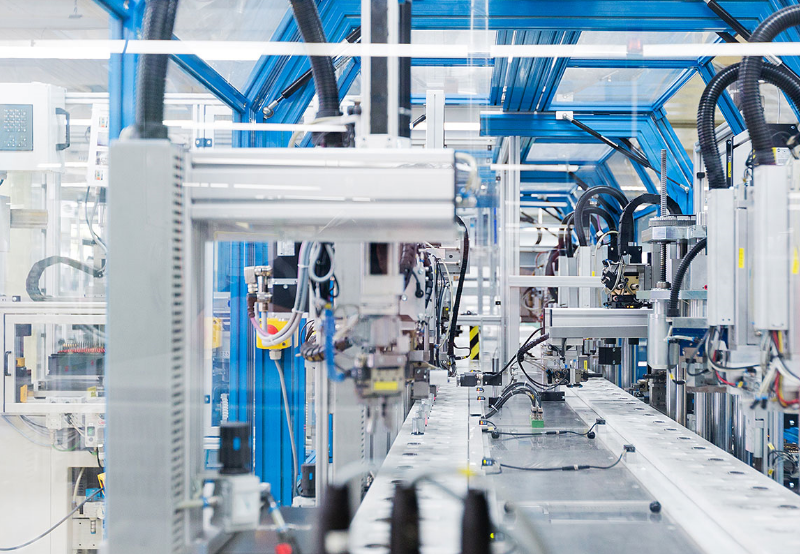

Endurance test benches

All imx electric motor test benches are basically designed for endurance testing. However, since endurance operation often has special requirements in terms of design and construction, imx also offers adapted endurance test benches. For example, these have a few testing tasks that then run for several weeks or months. To make testing efficient, 2, 3 or 6 load strings are often operated in parallel, and operation in a temperature or climatic chamber is also possible. In close coordination with the customer, the test sequences and the response to DUT failures or to undesired parameter changes are defined.

Automotive components in particular often have to be tested and validated according to a specific customer specification or standards such as LV 123 /124 / LV 148. With our modular and flexible testing software, such customizations are possible.

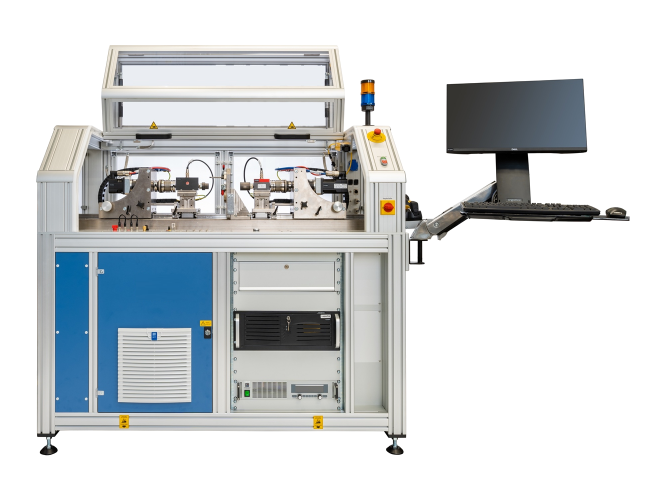

Production test benches

Electric drives, such as DC or EC motors, are becoming increasingly common in the automotive sector. There is an increasing demand for 100% inspection of the motors for fault detection and analysis as well as for quality statistics without increasing the cycle times of the production process. Test rigs can be set up with a classic load train consisting of a load machine and a torque sensor or the loadless parameter identification method can be used.

Production test benches with classic drive train

Test benches for the end-of-line area with a classic load line can be implemented as a partially or fully automated system. Coupling to the drive train is either done manually or automatically. Depending on the geometry of the DUT, the force transmission from the test object to the test rig load train is realized in a form-fit or frictional connection.

The connection of a hand-held scanner or a stationary scanner enables to read the information of the DUT. Based on this information, imx OMEGA prepares the test configuration and starts a test plan that performs all the necessary tests on the motor.

After they are completed, the results are stored in a database or transmitted to a control center. The test result can additionally be displayed on the screen or with a signal light.

Production test benches with parameter identification method

In recent years, there has been a shift from DC motors to electrically commutated (EC) motors in (safety) critical vehicle applications. The test specimen should be optimally used in terms of the best possible efficiency with a required torque curve.

There are some challenges to overcome in the process. In addition to accurately identifying the relationship between the magnetic flux and the current, the optimal control sequence, based on the flux ratio, is to be programmed into the power electronics (ECU). If possible, individually adjusted to each motor controller. The requirement is extended by the demand for short test sequences and a simple set-up.

The imx model-based parameter identification (PI) method enables testing without a separate load machine; the motor is loaded dynamically. The motor parameters, such as resistance, inductance and friction are determined within a few seconds. The model parameters fully represent the motor’s behavior and make it possible to monitor the production based on limit values and trend statistics. Using the parameters of the model, it is possible to calculate the characteristics of the motor, e.g. the characteristics curve.