imx BG80

All-rounder for applications up to 2,000 W

Test bench solution for applications up to 2,000 W

In the development of new electric motors and drive concepts, afast and efficient identification of characteristic values is crucial for the project to run smoothly. With automated tests and immediate calculation of results from the recorded measurement data, imx supports numerous customers in optimizing their testing processes. The imx standard development test benches for DC and EC/BLDC motors represent a cost-effective and quickly available alternative to a customer-specific test bench.

Based on our modular system, test stands can be realized in different performance and accuracy classes with speed / torque ranges and voltage / current ranges specially adapted to the application.

The flexible design of the base frame in the Expert version allows components to be integrated at a later date. These include e.g.

- the electromechanical connection of a thermal or climatic chamber

- the integration of an additional speed / torque range by adding a planetary gear.

All test stands are equipped with safety technology. They are designed in accordance with the Machinery Directive 2006/42/EC and are supplied with an EC Declaration of Conformity.

Power up to 2,000 W

Speed up to 20,000 RPM

Torque up to 50 Nm

Voltage up to 1000 VDC

Current up to 170 ADC

Controller for DC / EC / AC

We adapt our standard to your requirements!

If the above limits do not fit your application, please feel free to contact us.

In our test benches, we rely on measurement equipment from imc Test & Measurement GmbH. This has a sampling rate up to 100 kHz and an analog bandwidth up to 48 kHz. Depending on the design variant of the test bench, the integrated measuring system can be extended with additional measuring channels. In order to control DUTs or to connect to other components such as converters, control stations, etc., various fieldbuses such as CAN, LIN, EtherCAT, Profinet and many more can be integrated into the test bench.

In addition to the possibility of driving the DUT with a customer’s own controller, we offer the integration of universal controllers for the motor types DC, EC and AC.

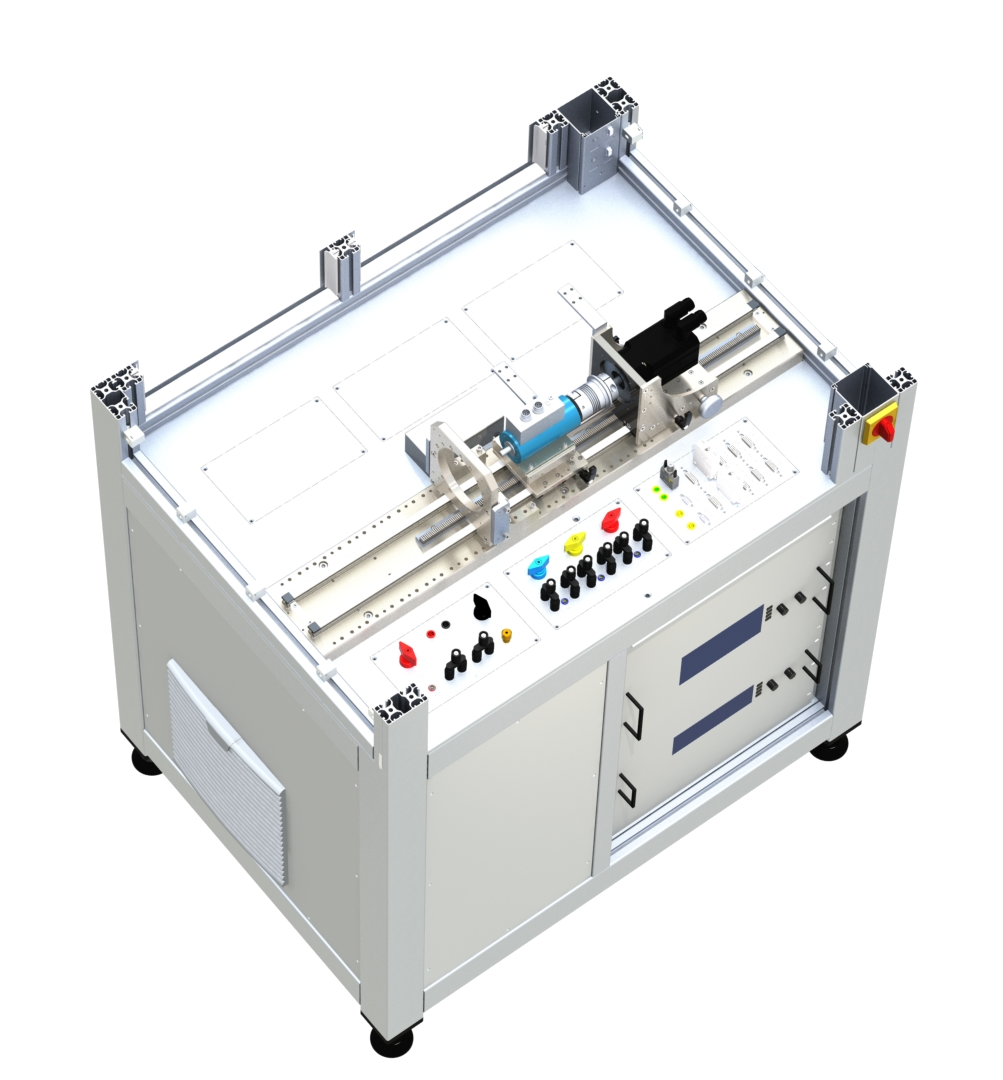

imx BG80 Expert

imx BG80 Expert

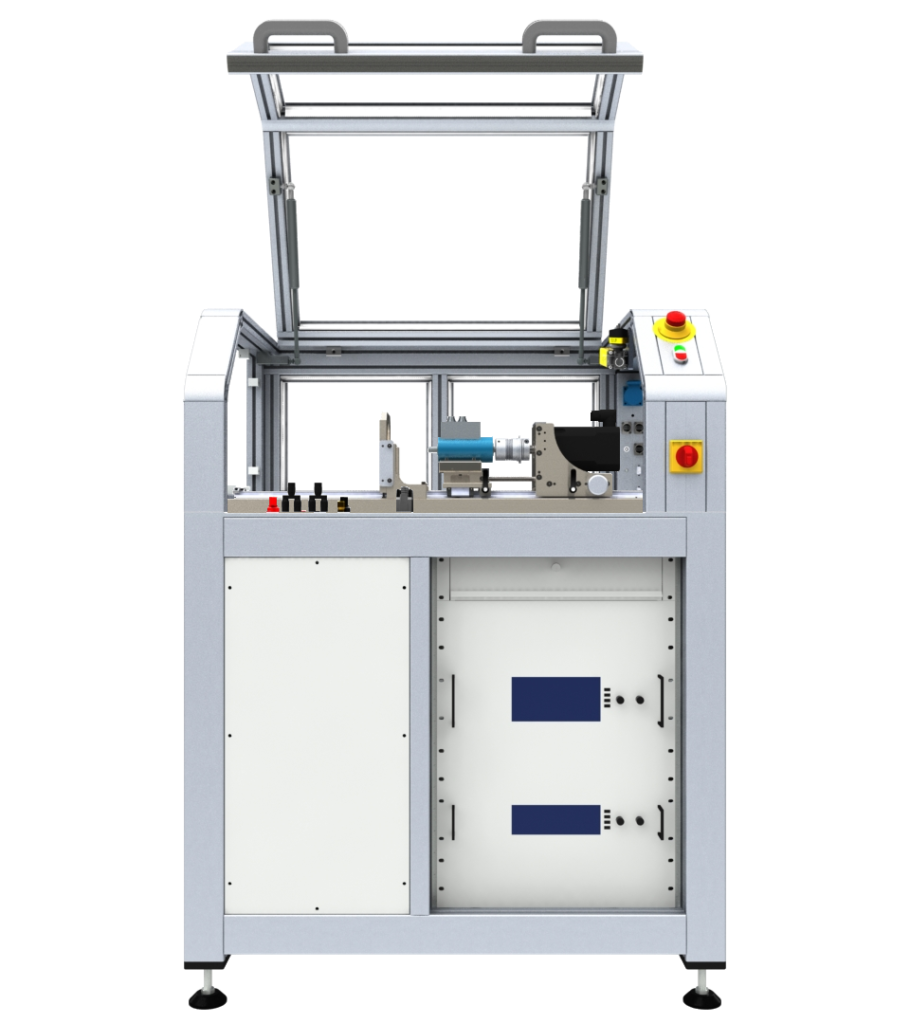

For simple and easily accessible mounting of the DUT in the test area, the hood can be opened upwards using the folding mechanism. The base provides wiring space and fits multiple 19″ rack-mount units, eliminating the need for additional control cabinets. The main switch of the test bench and other operating elements, such as the emergency stop button, are integrated in the side frame. The measurement equipment integrated into the test stand can be easily expanded at a later date via an interface in the test area.

imx BG80 Expert

The test area is additionally accessible via maintenance doors. These can only be opened with a tool. Optionally they can be equipped with a safety locking mechanism. The power supply of the test bench can be designed either as a fixed power supply or with a CEE plug connector. The interface panel provides all required interfaces for the user.

imx BG80 Expert

Up to six different interface panels can be used in the test room. For example, the DC outputs of the DC power supply or the three motor phases of the integrated controller are available to the user. In the Expert version, all surfaces are anodized or chemically nickel-plated.

imx BG80 Expert

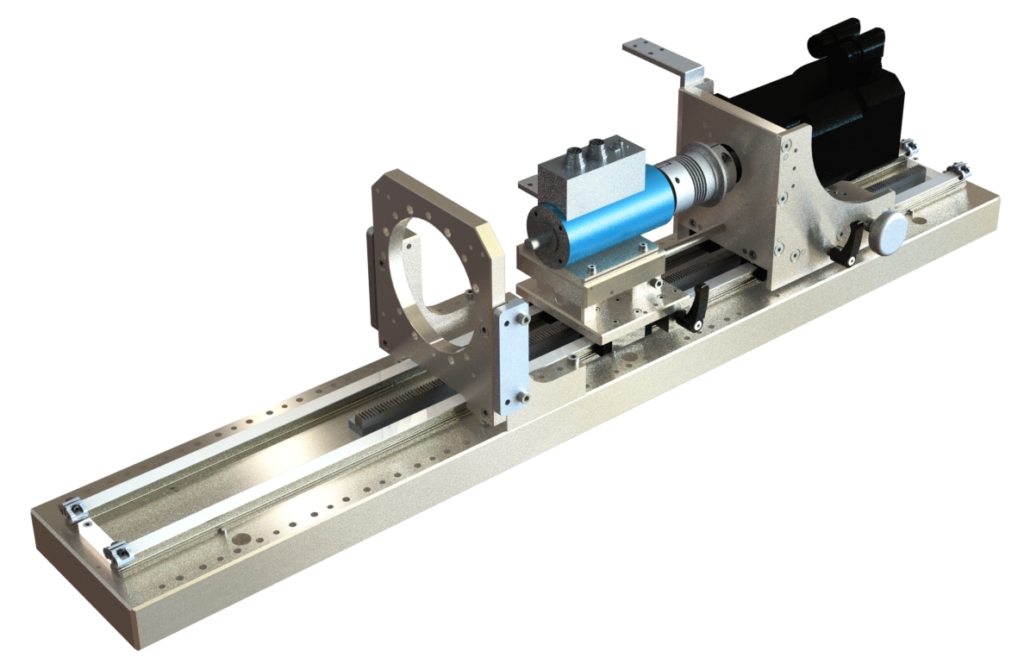

The drive train offers the maximum precision and comfort in the Expert version. The DUT fixture, torque measurement shaft, and the load machine are aligned with a laser so that misalignment is reduced to a minimum. The standardized DUT fixture can be positioned in the defined grid on the test bed without losing alignment. For example, it can be moved to the left to test the DUT inside a climate chamber. The assembly of torque measuring shaft and loading machine can be easily moved on the test bed by using the adjusting wheel and can thus be adapted to any situation. In addition, the two components can be separated from each other so that an optionally available planetary gear can be mounted. This modifies the speed / torque range. The torque sensor can be replaced within a very short time without the need to realign the components.